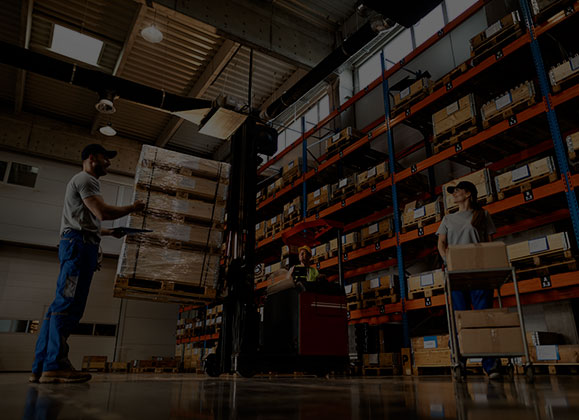

ABA Ultima Blown Film Line

ABA Ultima Blown Film Line

The most important data at a glance

| Polymer | HM, HDPE, LDPE, LLDPE, CACO3 , Recycled, Bio Degradable/Bio Compostable |

| Thickness Range | 20 – 80 µ |

| Layflat Range | 330 – 800 mm |

| Output | 65 – 80 Kg/Hr |

ABA Ultima Blown Film Line

Perfect for you because

Simple in Design

Easy in Operation

Compact & Efficient

Product Video :

ABA Ultima Blown Film Line

Technical Specification

|

Model Name : ABA Ultima Compact Type Three Layer Blown Film Plant |

|

Material Used : HM, HDPE, LDPE, LLDPE, CACO3 , Recycled, Bio Degradable/Bio Compostable |

|

Output Range : 65 - 80 Kg/Hr (Depends On Extruder’s Size) |

|

Screw Diameter : 35 / 45 mm (Customized) |

|

Screw L/D : 30:1 |

|

Layflat Range : 330 - 800 mm |

|

Thickness Range : 20 – 80 µ |

|

Optional Devices : Optional Devices:Twin Loader with Dryer, Corona Treater, Extra Die, Chiller, Heat Exchanger Embossig Roll, Air Shaft, Two Station Surface Winder |

ABA Ultima Blown Film Line

Select Your Model (Can select more than one model)

ABA SE3F 750-35/45

- Screw Diameter: 35/45 mm

- Layflat Range: 330 – 650 mm

- Max. Output: 65-70 Kg/Hr

- Thickness Range: 20-80 µ

- Optimum Thickness Layer Ratio: 1/4/1

ABA SE3F 900-45/45

- Screw Diameter: 45/45 mm

- Layflat Range: 450 – 800 mm

- Max. Output: 75-80 Kg/Hr

- Thickness Range: 20-80 µ

- Optimum Thickness Layer Ratio: 1/4/1

Give Us Some More Information

Q1. Materials (Can select more than one model)

HDPE

LDPE

LLDPE

BIO

Others

Q2. Film Width

Minimum

mm (

inch )

Maximum

mm (

inch )

Q3. Thickness

Minimum

micron (

mm )

Maximum

micron (

mm )

Q4. End Product

T-shirt bags / Shopping bags

Bottom sealing bags

Industrial bags

Garbage bags

Bag on rolls

Table Covers / Sofra rolls

(Sufra rolls)

Mattress

Shrink Films

Flat film rolls

Others

More shubham blown film lines

WE WILL GLADLY ADVISE YOU PERSONALLY

Looking for the right solution? We would be happy to advise you on which solutions best suit your needs. We are happy to help you make the right decision based on your individual requirements.

Mo. : +91 6357770050

E-mail : marcom@shubhamextrusion.com

Click here for personal advice